BeltPro QuickLag is an ideal solution for lagging of pulleys. It’s easy slide system allows users to quickly install new lagging, as well as replace worn out strips.

QuickLag offers higher adhesion to the drum as it is hot lagged versus the cold lagging process normally employed at site. No specialists needed, hence replacement can be done at short notice.

With various grades of rubber, BeltPro QuickLag offers you the ideal product to provide better coefficient of friction at Drive pulleys. It also protects the Pulley and the Conveyor belt from damage.

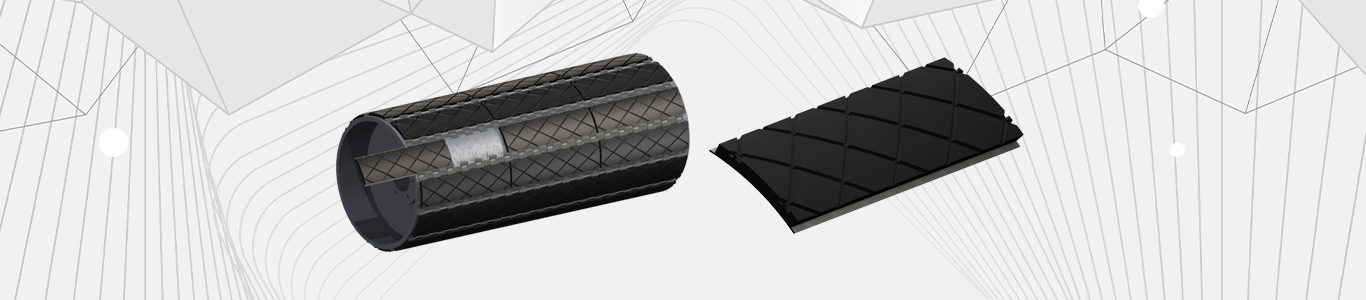

QuickLag consists of strips of Rubber bonded to a steel backing plate which is specially formed to fit flush against the surface of various pulley diameters. These plates are designed to slide in and out of retainers which are welded or bolted to the face of the pulley.

Benefits of BELTPRO QuickLag

Quick Replacements:

- Replacing lagging requires only sliding out the worn out strips and sliding in the new lagging strip

- No Special Equipment, Cold Solution or other Adhesives required.

- No Intensive labour required to handle large lagging sheets.

- No need to free the pulley from the belt.

Reduce Inventory Costs:

- Standard lengths of slide lagging can be stored in inventory regardless of pulley sizes.

- The strips can be cut to length depending on quantity required.

- Only replace the strips that are damaged, not the entire sheet.

Better Traction:

- BeltPro’s rubber compounding, in addition to its specially designed groove patterns, offer better traction especially in slippery conditions.

- Ceramic Lagging is also available for wet applications and where higher coefficients are required.

Specially designed to prevent any buildup of material on the lagging surface.

Better Bonding:

- The Rubber strips are hot bonded to the steel plates thus providing better bonding as compared to traditional lagging which is done using Cold Adhesives.

The retainers are welded or bolted to the pulley, resulting in a permanent bond preventing any lateral movement of the lagging strips.

Installation:

- Simply ease the tension on the belt to allow it to rotate.

- Then, weld or bolt the retainer strips to the pulley face.

- Slide the QuickLag Strips in to the slots and lock in place.

- Re-tension the belt and resume operation of the conveyor.

Replacement:

- Simply loosen the locking arrangement.

Remove the damaged strip by hammering one side of it and replace with a new BeltPro Slide Lagging Strip.

QuickLag HDX

- Ceramic chips inserted in the strips provide higher coefficient of friction thus providing significantly higher traction on the belt.

- Ideal for wet conditions where there is slipage.

QuickLag 50

- Lower hardness strips of 50 shore A with better Abrasion Resistance results in longer life of the rubber strips.

QuickLag R45

- For Superior life in highly abrasive conditions, QuickLag R45 provides Superior Abrasion Resistance of 90 mm3.

- Optional Red Color available.

QuickLag FG

- Specially formulated lagging designed for Food Grade applications.

- Available in White and Blue colors.

QuickLag HR & HRX

- Perfect for high temperature applications like Cement Plants.

QuickLag FR

- Special FR Compounding where self extinguishing properties are required.

- Used in Thermal Plants, Underground Mining and Fertilizer Plants.

QuickLag OR, CR & SCORF

Lagging is also available in Oil Resistant, Chemical Resistant or Static Conductive Oil Resistant and Flame Resistant (SCORF) properties.